THE PROOF IS IN THE PRODUCTION.

It’s one thing to talk a good game. But we have the

successful projects to demonstrate the power of our ONE MODEL™

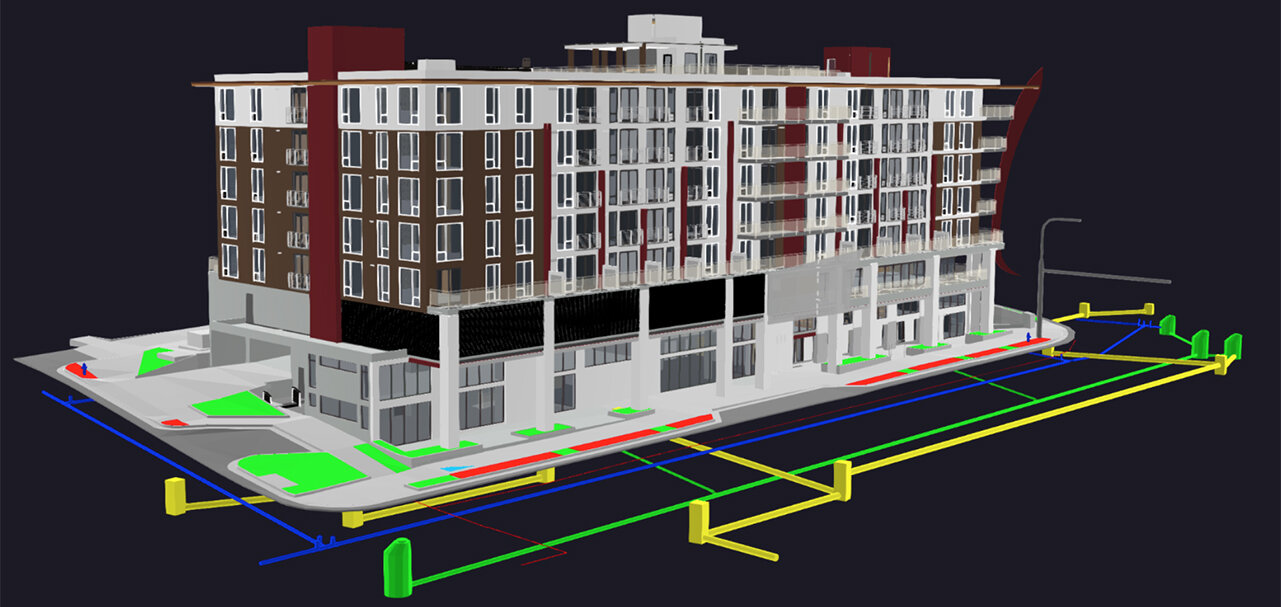

THE EAGLE POINTE APARTMENTS, a planned multi-family community in Bremerton, WA.

A simple model can inform the entire life cycle of the project by including essential data with every object in the graphical representation that people see with the ONE MODEL.™

This view in time shows combined MEP and Civil models created from different software but coordinated into ONE MODEL™ for review, materials takeoff, construction sequencing and eventually operations. Every object is visible, has a relationship to all other objects, and is developed along its entire time line as a whole instead of pieces. This is ONE MODEL.™

Each component has data comprised of precise characteristics (example at right). The metadata of that component can be specified by the owner so only useful information is shown and that in turn can be used for other purposes, such as maintenance.

Rendering of the Eagle Pointe Apartments rooftop view. Amenities generated by ONE MODEL.™

THE EAGLE POINTE APARTMENTS is located in a vibrant community in Bremerton, WA.

MAPLE STREET CORRECTIONAL FACILITY, San Mateo, CA.

GPLA and Bourland and Associates were hired by the GC to correct structural miscalculations by another construction firm which had resulted in a costly delay of several years. All documentation was available on laptops or iPads, accessible on site with ONE MODEL.™ All participants could view what was being installed in real time while walking the site.

Using ONE MODEL™, we used a combination of design and construction criteria to create the prefabricated, full height exterior wall sections, then used ONE MODEL to schedule when they would be lifted into place.

DAYTONA INTERNATIONAL SPEEDWAY, Daytona, FL.

The GC was committed to a liquidated damages ($10 million) contract when Bourland and Associates and GPLA were hired to coordinate prefabrication and erection design of over 1 million square feet of new construction within the existing old structure of the Grandstands.

By incorporating all models for all trades into ONE MODEL™, the walls and exterior cladding were prefabricated, brought on site, erected, and all construction was finished two weeks ahead of schedule, ultimately saving the $10 million in liquidated damages.

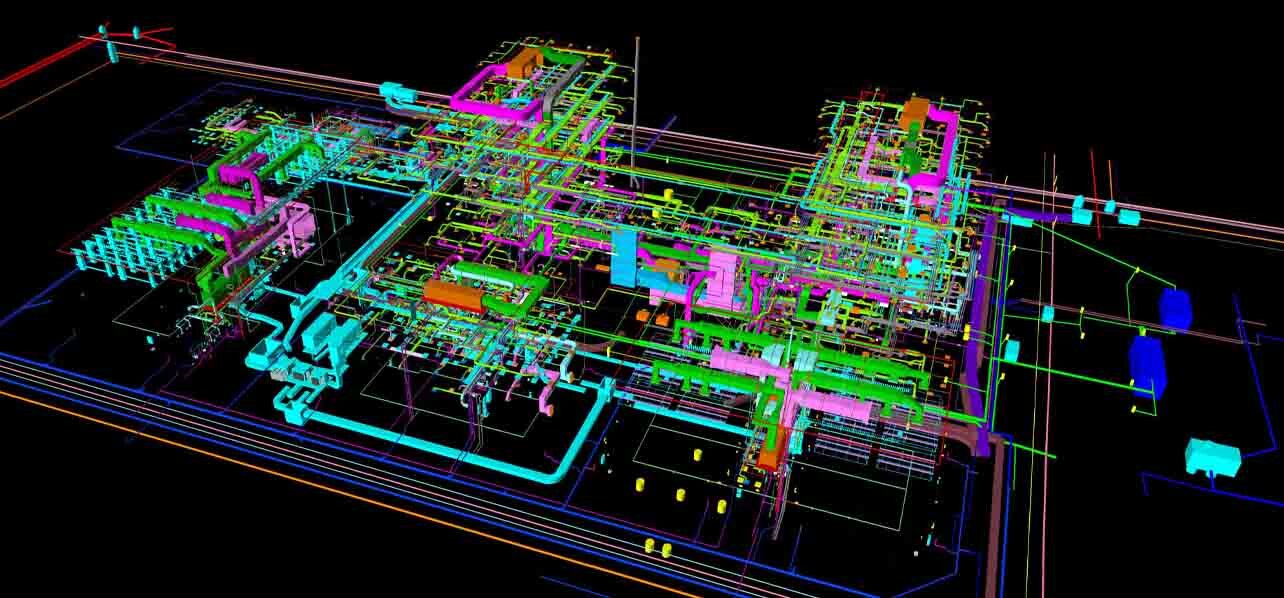

USC SCHOOL OF CINEMATIC ARTS, Los Angeles, CA.

A single instance in the ONE MODEL™ development showing the MEP and Civil infrastructure of the first buildings at USC. This model was “alive” and modified during construction. Today it is modified on an “ongoing basis” reflecting changes brought by maintenance and operations.

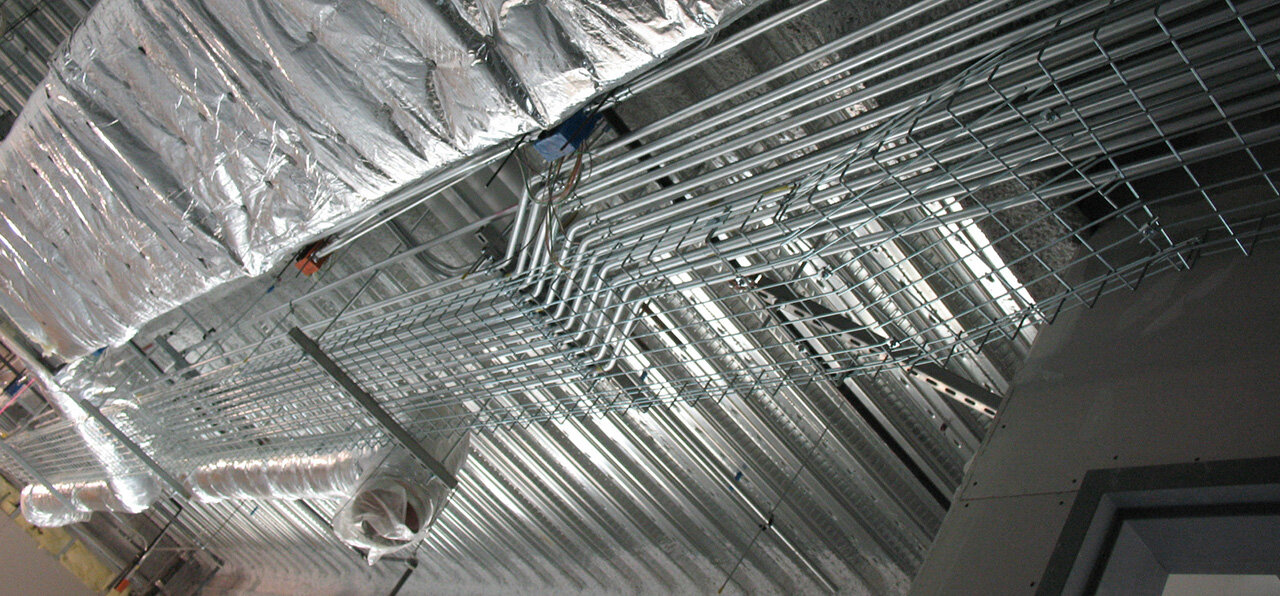

Since all trades worked with ONE MODEL™, a large portion of the infrastructure could be prefabricated. Long pipe runs like these could be lifted directly into position located by laser measurements so that entire floors were completed in a few days. The result: less waste, safer working conditions, faster erection times, greater savings overall, and no change orders.

The electrical conduits were a prefabricated design using ONE MODEL™ strategy. They were simply lifted into place, saving weeks of installation time.

The ONE MODEL™ showed what parts and structures were to be fabricated and where they were to be installed. When it came to the finish of the Gothic style ceiling it required the knowledge and skill of craftsmen. The ONE MODEL™ simply insured that the craftsmen had individual pieces precisely fabricated for the specific location they would be needed.

A graphic representation of the site when construction was complete. This view is a combination of all separate disciplines’ models (Architecture, MEP, Structure, Civil, Interiors, Landscaping etc.) combined into our ONE MODEL™ view.

HALIBURTON REGIONAL CORPORATE CAMPUS, Ciudad de Carmen, Mexico.

This project is an early example of multiple private and government agencies sharing information simultaneously to collaborate on construction of the infrastructure and design of a new port facility. All trades worked together sharing plans, resources and even materials. The ONE MODEL™ concept was used as all agencies worked toward a common goal.